Motivation

A geological compass is an essential tool in the geologist’s field kit. It is used in various

geosciences disciplines, including geological mapping and structural geology. The past

decade has seen the emergence of digital geological compasses through excellent smartphone

or tablet apps (e.g., FieldMove Clino, eGeoCompass, Stereonet Mobile), the reliability of

which has been demonstrated for teaching and research purposes (e.g., Novakova and Pavlis,

2019; Lundmark et al., 2020). Although these digital compasses are highly ergonomic and have

greatly improved the speed and the rate of data collection (Zobl et al., 2007; Allmendinger

et al., 2017), it is essential that undergraduate students learn how analog geological

compasses work and how to use them to characterize the orientation of given geological

structures (i.e., foliations, lineations, or a combination of both) and transcribing this

information in the right format in a notebook. What is the minimum requirement for a

geological compass? It must be equipped with a clinometer, a precision magnetometer—ideally

with a fixed circular graduation—a measuring reference trench, and a bubble level. Various

geological compasses are available on the market (e.g., Brunton, Freiberg, Topochaix brands)

with several models in different price ranges. Nevertheless, equipping large student groups

with robust, accurate, semi- to fully professional models of geological compasses still

represents a significant cost. This is why I initiated the PYC (Print Your Compass) project,

building upon the emergence of affordable digital fabrication tools such as 3D printing,

which is particularly facilitated by the development of shared workspaces such as FabLabs

and creation networks in academic institutions and/or universities (Hasiuk, 2014; de Lamotte

et al., 2020; Reynolds et al., 2020).

This paper aims to provide detailed 3D plans of compass pieces, guidelines for printing

materials, magnets and pivot system, and validating the accuracy of printed compasses. I

hope that such initiatives will allow students from their first degree to master’s level,

teachers, and geoscientists in general, to print their geological compass at a lowered cost,

adapted to their specific needs, and with sustainable manufacturing.

How to Print Your Compass

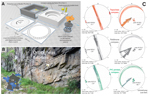

The PYC compass (v.0.94) presented in Figure 1A is designed in five modules. Part 1 is the

core of the compass, printed here using Selective Laser Sintering (SLS) in rigid Nylon

Polyamide (PA12) with a printing resolution <80 µm. The front side of Part 1 is made of a

cylindrical cavity embedding the precision compass, and the back side is marked by a

circular gully in which a 2-mm-wide brass ball will be used as a clinometer. Part 2

comprises the magnet and pivot system. It is made of a pile of three stacked pieces printed

using SLS–PA12 (Fig. 1A) in which a brass pivot and four Nd-magnets (15 mm long × 3 mm in

diameter) are enclosed. The magnet and pivot system is ultimately stacked and sealed by two

vertical nylon screws. The magnet and pivot system is balanced on a brass nail crossing Part

1 vertically. Part 3 and Part 4 are the closing windows placed on each side of the PYC

compass. They both consist of a 2-mm-thick and 80-mm-side square plexiglass window. They are

crucial parts of the compass as they display the graduations for precise measurements. Part

3 comes with inclination degrees from 0 to 90° (with a precision of 2°), and Part 4 is

graduated from 0 to 360° for azimuth measurement respective to north (with a precision of

1°). Graduations can be directly printed onto plexiglass pieces or as transparent flipped

vinyl stickers placed on their inner side. Small nylon screws are used to fix these windows

to the main part of the PYC compass. Part 5 comprises two levels and the casing of the PYC

compass. One rounded level (15 mm in diameter and 8 mm in height) can be embedded on the

front side of the PYC compass to enable levelling, along with a second cylindrical level on

the side of the PYC compass to improve finding the line of slope on a planar structure. The

protection case, printed here in a flexible resin (thermoplastic polyurethane), is designed

to laterally slide the PYC compass in it and act as a shock absorber. The whole compass is

10 × 10 × 2.3 cm in size and weighs less than 0.25 kg. It can be easily disassembled, and

each of the constitutive pieces can be replaced. The 3D models can be found in the

supplemental material1 or here: https://skfb.ly/opCJY. These are licensed under a Creative

Commons Attribution 4.0 International License (CC BY 4.0).

Figure 1

Figure 1

(A) Disassembly view of the “Print Your Compass” (PYC) 3D models. (B) Field picture showing

the outcrop on which the PYC compass was tested. The outcrop displays an augen orthogneiss

massif with foliations slightly dipping to the NNW, itself crosscut by late joints and

faulted structures. Lower left is a sketch map of the French basement in blue locating the

French Massif Central and the investigated outcrop (yellow star). (C) Two columns of

comparative Stereonet plots. The first column shows measurement of the subvertical joints

and faults, the second shows the measurement of foliations. Poles of planes are shown with

the average value as a blank square. Rose diagrams show the distribution of strikes’

azimuths. These plots were done using the Geolokit app (Triantafyllou et al., 2017).

Validating the PYC Compass Accuracy in the Field

I tested the PYC compass in the field and compared measurements against reliable compasses,

including the Topochaix Universelle compass and the FieldMove Clino app running on a Samsung

S7 smartphone. The test was conducted on the Moulin de Cezinieux orthogneissic unit located

in the northern Pilat region (eastern French Massif Central; Fig. 1B). This outcrop is made

of low-dipping metamorphic foliations from the late Hercynian orogenic collapse (e.g.,

Gardien et al., 2021). These ductile structures are crosscut by recent subvertical joints

and faults. Tests were made on these two types of structures with twenty planar measurements

for each compass: (i) Concerning foliation measurements, using the FieldMove digital

compass, the mean strike direction is N229.0 ± 6.6° (95% polar confidence), and the mean

dipping value is 22.2° to the NW. For the Topochaix Universelle compass, the mean strike

direction is N231.3 ± 5.0°, and the mean dip is at 20.9° to the NW. For the PYC printed

compass, the mean strike direction is at N232.7 ± 4.9° and the averaged dipping value was

20.7° to the NW with a radius of polar confidence at 5% of 2.35° (Fig. 1C). (ii) Concerning

the subvertical joints and faults measurements, the FieldMove digital compass provides an

averaged strike direction of N344.2 ± 2.7° and a mean dip at 87.2° to the E. For the

Topochaix Universelle compass, the mean strike direction trends to N339.6 ± 1.5°, and the

mean dipping value is 89.9° to the E. The PYC compass provides a mean strike direction at

N341.9 ± 1.7° and an averaged dipping value at 86.1° to the E (see Fig. 1C). The reliability

of the PYC compass is attested first by the small polar differences between PYC mean pole

values and those measured with the Topochaix and the FieldMove Clino app, which yields 4.4°

and 2.5°, respectively, for the foliation structures and 0.2° and 15.0°, respectively, for

the joint/faulted structures; and second by the small radius of polar confidence at 5% of

2.35°, indicating a reduced data spread and a good reproducibility during structures

measurement.

Acknowledgments

The author acknowledges support from the Université Claude Bernard de Lyon and the LGLTPE

laboratory for the grant: “Bonus Qualité Recherche–EC 2021.”

References Cited

- Allmendinger, R.W., Siron, C.R., and Scott, C.P., 2017, Structural data collection with

mobile devices: Accuracy, redundancy, and best practices: Journal of Structural Geology,

v. 102, p. 98–112, https://doi.org/10.1016/j.jsg.2017.07.011.

- de Lamotte, D.F., Leturmy, P., Souloumiac, P., and de Lamotte, A.F., 2020, Using 3D

printed models to help the understanding of geological maps: Copernicus Meetings, no.

EGU2020-8757.

- Gardien, V., Martelat, J.E., Leloup, P.H., Mahéo, G., Bevillard, B., Allemand, P., and

Fellah, C., 2021, Fast exhumation rate during late orogenic extension: The new timing of

the Pilat detachment fault (French Massif Central, Variscan belt): Gondwana Research,

https://doi.org/10.1016/j.gr.2021.10.007.

- Hasiuk, F., 2014, Making things geological: 3-D printing in the geosciences: GSA Today,

v. 24, no. 8, p. 28–29, https://doi.org/10.1130/GSATG211GW.1.

- Lundmark, A.M., Augland, L.E., and Jørgensen, S.V., 2020, Digital fieldwork with

Fieldmove—How do digital tools influence geoscience stu-dents’ learning experience in

the field?: Journal of Geography in Higher Education, v. 44, no. 3, p. 427–440,

https://doi.org/10.1080/03098265.2020.1712685.

- Novakova, L., and Pavlis, T.L., 2019, Modern methods in structural geology of

twenty-first century: Digital mapping and digital devices for the field geology, in

Mukherjee, S., ed., Teaching methodologies in structural geology and tectonics:

Singapore, Springer, p. 43–54, https://doi.org/10.1007/978-981-13-2781-0_3.

- Reynolds, M., Waldron, J.W., and Marin, L.F., 2020, 3D-printed models: Tools for

teaching 3D visualization of subsurface geology: AGU Fall Meeting Abstracts, v. 2020, p.

ED002–0001.

- Triantafyllou, A., Watlet, A., and Bastin, C., 2017, Geolokit: An interactive tool for

visualising and exploring geoscientific data in Google Earth: International Journal of

Applied Earth Observation and Geoinformation, v. 62, p. 39–46,

https://doi.org/10.1016/j.jag.2017.05.011.

- Zobl, F., Brunner, F.K., and Wieser, A., 2007, Development of a digital geological

compass: Quarterly Journal of Engineering Geology and Hy-drogeology, v. 40, no. 3, p.

301–308, https://doi.org/10.1144/1470-9236/07-008.